Product Testing

Our cover materials are rigorously tested to ensure they perform as advertised. You can trust us to protect your assets.

At EmpireCovers, we scientifically test our products to ensure that they consistently perform as advertised. Our Research and Development Team has developed protocols to measure our covers’ effectiveness against the very elements that could damage your investment. These protocols involve the use of ASTM standards and very precise scientific equipment, as outlined in each report.

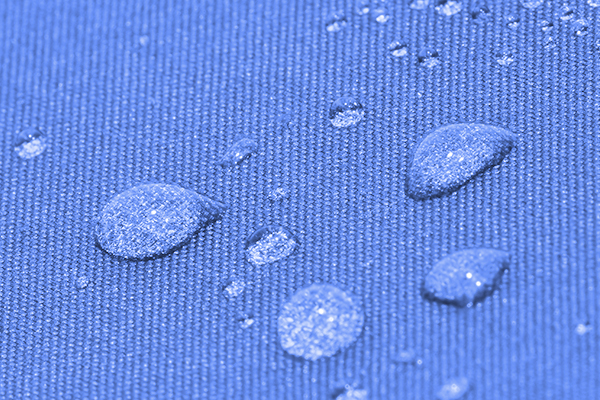

Our products undergo rigorous testing by an independent third party to ensure the best quality. These tests assess the colorfastness, breaking strength, hydrostatic resistance, water repellency and water resistance of our products. Through independent testing, we can ensure the accuracy of our product performance and that our products can withstand the elements with proven results.

Waterproof Test

In this test, we investigated the water-resistance and repellency of several covers. Our test method measured the car covers’ resistance to the penetration of water under hydrostatic pressure, both on the cloth samples and seams. Additional samples were subjected to a spray test and a rain test.

UV Weather Test

Exposure to outdoor climates has a particularly adverse effect on most types of surfaces, car covers included. To ascertain the weather-resistant properties off our covers, we subjected fabric samples to cycles of high UV radiation, moisture, and temperature, and then measured the material and cross-material tensile strength of each.

Interior Temperature Test

On a 90 degree day, a closed car’s interior can reach a staggering 138 degrees. We tested the temperature protection offered by four different covers, as well as a windshield mounted reflector. Our methodology included outfitting 4 adjacent cars with custom-built temperature, humidity, and light sensor, as well as data loggers to capture all the data.

Scratch Resistance Test

A car cover is only as good as the surface that comes in direct contact with the car’s exterior. In this test, we tested the interior cloth of four different covers, with 150 grit sandpaper used as a control. We then custom-built a scratch-testing device and vibrated each material against a finished plate of 18 gauge steel at 45 lbs. of pressure.

Durable Fabrics

Premier Protection Driven by Innovation.

EmpireCovers has developed and produced the most comprehensive range of proven, protective covers. All of our covers are made from cutting edge fabrics that are rigorously tested by our Research and Development Team, to ensure that we deliver high-quality, affordable covers directly to your doorstep.

Whether you are looking to protect your vehicle against heavy rain or harmful UV rays, we have a fabric that will cover your needs. Over the years, we’ve partnered up with materials leaders to bring innovative material technology to the protective cover markets. By means of vigorous research and customer feedback, we have selected materials that will stand up to a wide range of hazardous conditions, including precipitation, UV rays, corrosion, and more. We are proud that all of our cover materials are backed by industry-leading manufacturer warranties.

Polypropylene

A multilayer material that is UV treated, breathable and waterproof to effectively prevent degradation. This material makes for excellent protective covers.

Learn More

Marine Grade Polyester

Extremely waterproof and UV resistant, this material is woven with 150 – 1200 fiber deniers, making it excellent for heavy duty protection.

Learn More